Manufacturer’s Catalogues

concrete skin - special | Light & Concrete - Triennale Milano 2007

from Rieder

Product description

Formed Elements

With a specially developed process, U-shapes, arches and other geometric shapes can be manufactured using fibreC panels. Preformed parts are only available with a thickness of 13 mm and with the surface ferro and have the same product properties and advantages as concrete skin. Standard angle formats are in stock; special shapes and round arches are more time-consuming in their production and thus have a longer delivery time.

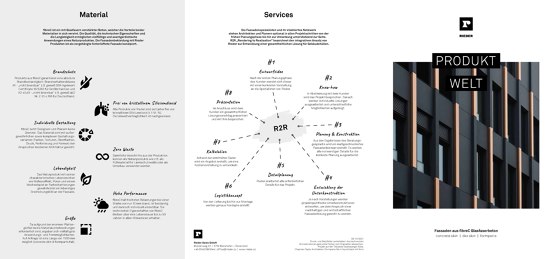

Light & Concrete - Triennale exhibition in Milano 2007

during the designweeks Fuori Salone del Mobile

Architect: 967 Architects Bolzano/Milano

Product Information:

200m² concrete skin

colour: bianco / liquide black

surface: matt / ferro

With a specially developed process, U-shapes, arches and other geometric shapes can be manufactured using fibreC panels. Preformed parts are only available with a thickness of 13 mm and with the surface ferro and have the same product properties and advantages as concrete skin. Standard angle formats are in stock; special shapes and round arches are more time-consuming in their production and thus have a longer delivery time.

Light & Concrete - Triennale exhibition in Milano 2007

during the designweeks Fuori Salone del Mobile

Architect: 967 Architects Bolzano/Milano

Product Information:

200m² concrete skin

colour: bianco / liquide black

surface: matt / ferro

More about this product

Part of the collection

FACADE DESIGN.

Manufacturer

Rieder

Family

Architonic ID

1071744

More products from Rieder

Downloads

Related Projects

Contact information

Address

Glemmerstraße 21, 5751 Maishofen Austria

This product has been discontinued.

More products from Rieder

More from

RiederContact information

Address

Glemmerstraße 21, 5751 Maishofen Austria