strasserthun works with a light

Text by strasserthun.

Thun, Switzerland

08.06.15

Considered the tool of the future, laser cutting and laser engraving of solid wood, veneer and other materials are available at strasserthun. Sawing, drilling and milling are also included in the company’s daily use. Strasserthun uses a specialised laser system that allows it to focus on quality and provide individual and filigree details. With contactless processing and virtually no stress or damage to the material, the possibility of new perspectives is created.

The laser system at strasserthun tailors to the needs of the interior design, furniture-construction and the semi-finished production output. In addition to craftsmanship, technology is needed to produce efficient, high quality products. The in-house laser system at strasserthun is important within its product development department especially in the production of the different interior design and furniture manufacturing parts. The easy to use lasers can be customized and specially designed for individually prescribed elements such as kitchen and bathroom cupboard fronts as well as furniture components, wall and ceiling covers.

With the innovative laser system, natural woods, veneers, MDF and countless other materials can be productively cut and engraved simultaneously. Even the finest contour curves and recesses below 0.1mm in diameter are effortless for the laser to implement. Using a cutter or saw for this process would be inconceivable. The design shapes that are based on sketches can be further advanced by means of software that can transfer the data into a manageable format. The laser machine can then show its force with contactless and almost noiseless machining of the base material. A further advantage that should be emphasized is the missing chip formation that makes the postprocessing and subsequent cleaning of the machine environment completely unnecessary. Chips, dirt and blunt tools are a thing of the past. The baseplates with a length up to 310 cm, a width up to 210 cm and a thickness up to 6 cm can be fully used through automatic nesting which reduces the waste to a minimum. The radius free laser tool can cut any contour shape without having to worry about tool limitations.

Due to this modern manufacturing, strasserthun can produce even more effectively when compared to traditional manufacturing methods. This results in significant time savings as well as quality advantages. Laser technology asserts itself in more and more areas and will continue to take a serious role in many manufacturing processes whether in individual interior design or furniture manufacturing. Strasserthun has prepared itself for these upcoming tasks and can currently meet the needs of its customers now and into the future.

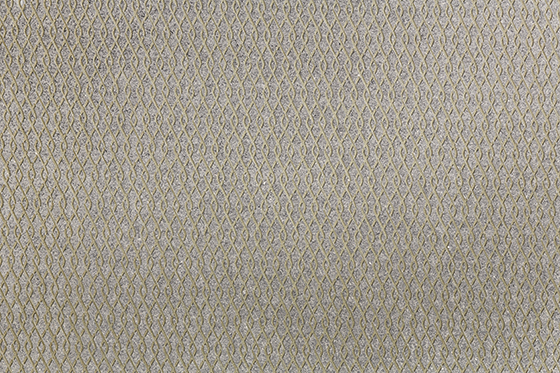

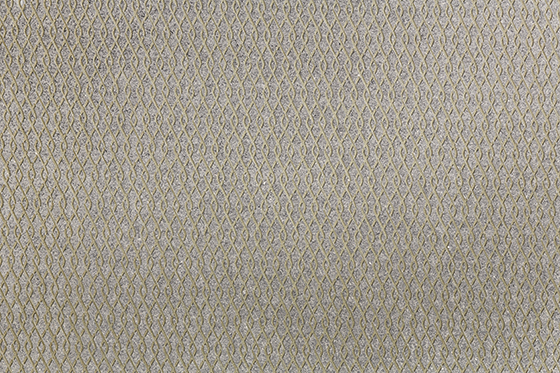

A taste of a semi-finished product. The pattern of the designer Pierre Mazairac, Lianel Spengler and Harry Hersche.

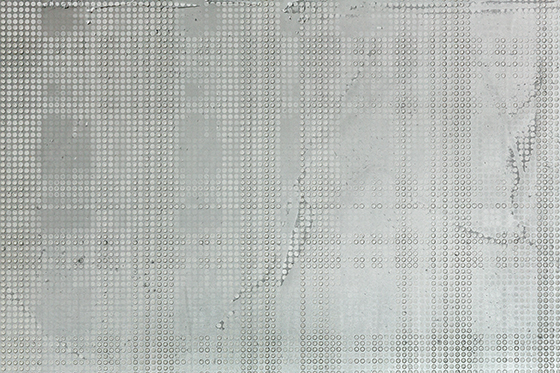

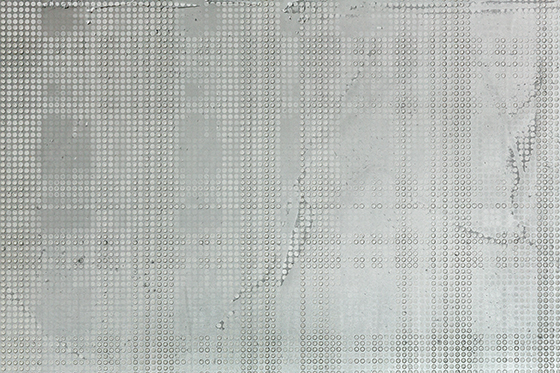

An example from the field of interior design. Designed by Lianel Spengler, the wall panelling pattern in punkt6 - the house of materials from strasserthun. The geometry of the pattern can be transferred to a material only through the use of laser technology.

And a perfect example from the design furniture sector; paravent LINK designed by Harry Hersche. The chosen pattern is a composition of two designs, a linear and a rounded form. The visual effect created by combining this pattern with oak help bring it to life.

....