Layer by layer: ARGOLITE

Scritto da Das Ideale Heim Magazin für Architektur, Design und Wohnkultur

Schlieren, Svizzera

12.01.21

There’s only one firm in Switzerland that produces high pressure laminate (HPL) sheets: ARGOLITE.

Melamine bath: It was the development of melamine resins that made it possible to produce the sheets with the necessary quality

Melamine bath: It was the development of melamine resins that made it possible to produce the sheets with the necessary quality

×The warehouses of the Argolite company in Willisau are jam-packed with huge rolls of paper. Most of the material comes from Europe, from Finland for instance – and in your mind’s eye you can’t help but picture the endless forests of the taiga that provide the feedstock for a building material by the name of HPL (high pressure laminate).

Based on thermosetting resins, it comes with an internationally recognised quality guarantee in the form of ISO certification. Argolite AG is the only firm in the whole of Switzerland that produces these sheets and is run by Markus Höchli, the third generation of his family to guide the company’s fortunes.

Markus Höchli, CEO ARGOLITE, is leading the family brand in third generation

It all started with his grandfather who, together with his brother, founded a plywood factory in Buchs in the canton of Aargau. In 1951, they bought a licence to produce plastic-coated particle boards from a West German company. Unfortunately, the fledgling process was still having teething problems because melamine resins were not yet available on the market. As early as 1953, the company switched from producing particle board coated with synthetic resin to making laminate sheets under the brand name Argolite.

Versatile: HPL sheets can be used for all sorts of interior finishings, as well as for facades. Here they’ve been used for cabinet fronts

Versatile: HPL sheets can be used for all sorts of interior finishings, as well as for facades. Here they’ve been used for cabinet fronts

×Although the choice of formats and finishes was still modest as compared to now, not much has changed when it comes to the production process. Even today, a lot of the work is still done by hand, despite investments of approx. 20 million Swiss francs over the last 10 years.

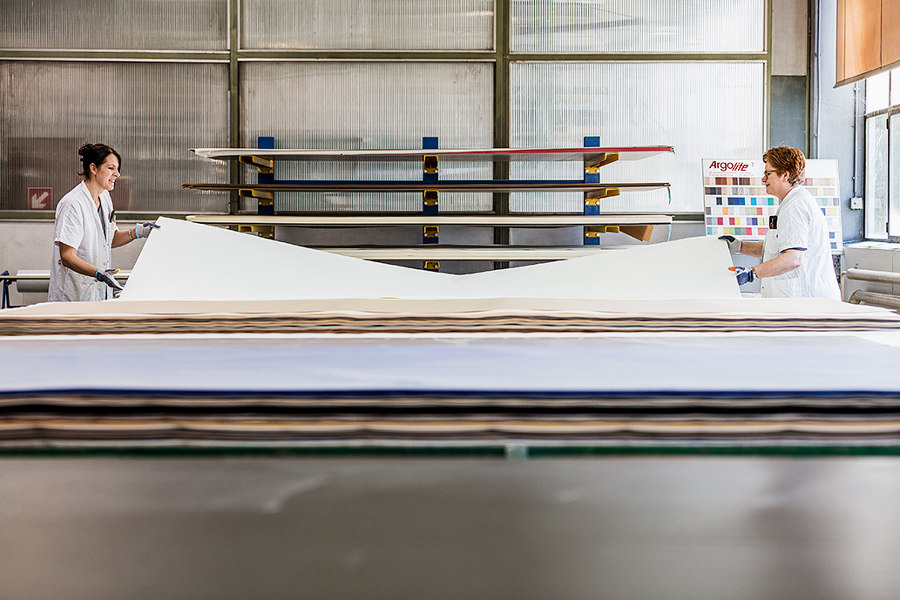

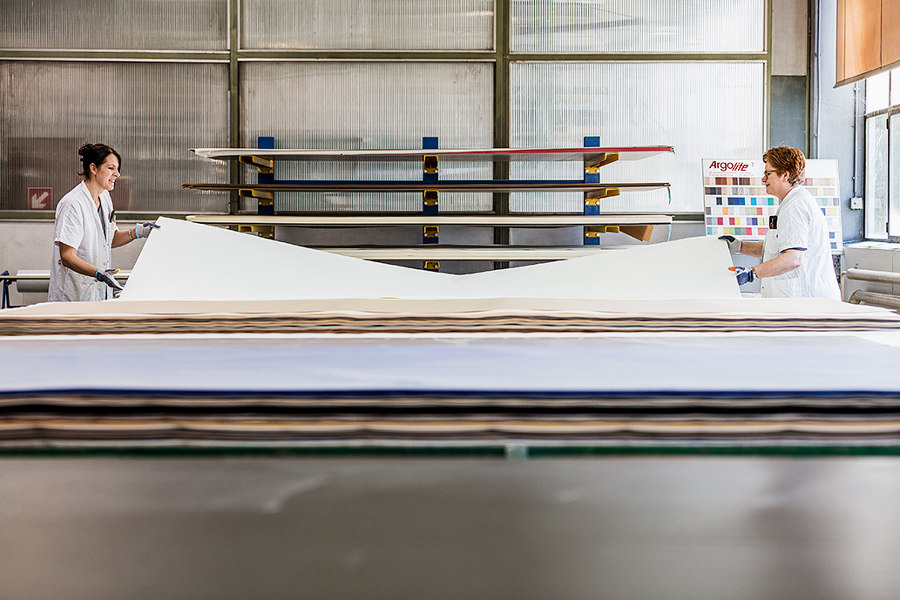

The lengths of paper are impregnated with melamine resin, dried and cut to sheet size. Then the individual pieces of paper are layered one on top of the other and, depending on the specific formulation, completed with a layer of special paper. The top layer can be embossed thanks to a metal plate. Several sheets are placed on top of each other and placed in the press together.

Step 1-3: After delivery, the paper rolls are stored according to the thickness. The paper is impregnated with melamine, dried and cut. And then the individual layers of paper are cleaned and placed on top of one another

Step 1-3: After delivery, the paper rolls are stored according to the thickness. The paper is impregnated with melamine, dried and cut. And then the individual layers of paper are cleaned and placed on top of one another

×Thanks to the high pressure and resulting heat, they form a highly compressed sheet which, depending on its composition, can even be used for outdoor applications. In addition, textiles, lengths of magnetic material, large-format prints and various other materials can be inlaid in the top layer as required.

Step 4 and 5: The prepared layers are pressed into a sheet. And lastly, the sheets are sorted and stored in the high-bay warehouse

Step 4 and 5: The prepared layers are pressed into a sheet. And lastly, the sheets are sorted and stored in the high-bay warehouse

×Because the production chain is configured for a batch of one, architects, interior designers and contractors can let their imaginations run free. The HPL sheet can also be equipped with special properties tailored to the intended application.

Photos: Lea Hepp; Markus Schneeberger

Text: Anita Simeon Lutz

Argolite HPL Werk

Ettiswilerstrasse 48

6130 Willisau

Tel. +41 (0)41 972 61 11

verkauf@argolite.ch