Architonic Concept Space III: Blow-up Statics

Texte par Nora Schmidt

Berlin, Allemagne

15.01.10

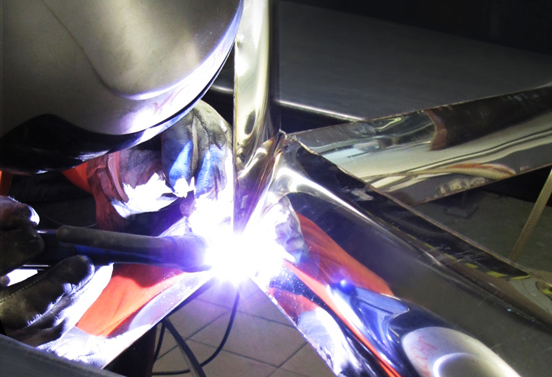

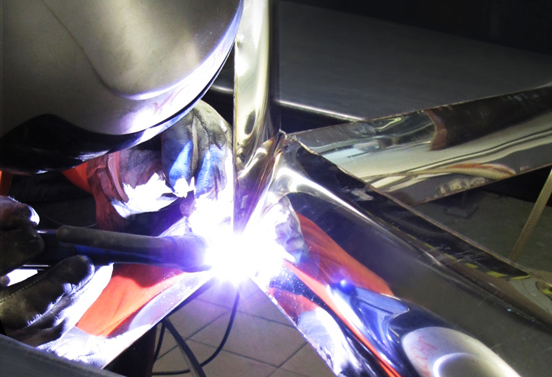

Making of Architonic Concept Space III, created by Zieta Prozessdesign

The final design has been ready since the New Year, and production began one week ago. Architonic Concept Space III, designed by Oskar Zieta (Zieta Prozessdesign) and the CAAD faculty at the ETH Zurich will be celebrating its premiere to coincide with the opening of this year's imm cologne on 19 January. In the second part of our 'Making of' report we would like to provide you with a few more insights into the manufacturing process.

It has to be modular and adaptable to varying stand sizes, easy to set up and dismantle time and time again, convenient to transport on a single truck etc. - this was the challenging briefing for the Architonic Concept Space. For Zieta it was an ideal opportunity to offer an initial demonstration of the versatility of his FiDU (Freie InnenDruck Umformung) light construction technique in an architectural context. This highly flexible technology, in which precision-cut and welded sheet metal sections are blown up under high pressure to form three-dimensional shapes, could almost have been created specially for this demanding task.

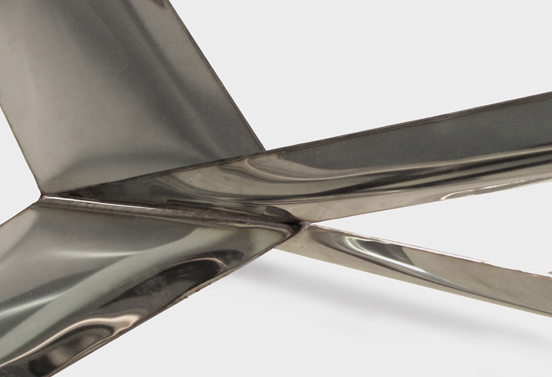

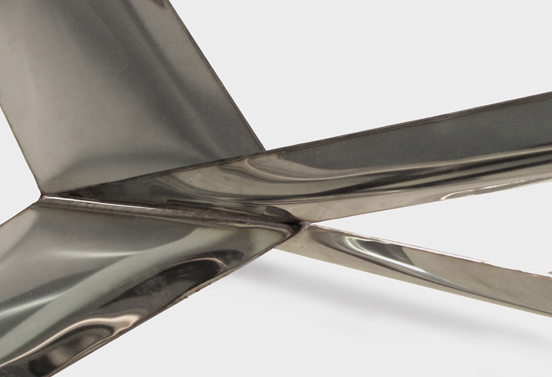

The result is a modular structure consisting of identical, inflated sheet metal modules. Depending on the stand size they can be placed next to one another, behind one another and even on top of one another. The core of the entire construction is the connecting points which bind the whole structure and distribute the forces involved across the supports and cross members, stabilising it in all directions.

"In addition to the strict specifications we of course also wish to use Concept Space to demonstrate the static capabilities of this technology. The use of the triangle as a recurring basic element enables us to create stable, relatively large and expressive spaces with minimal materials. A 3.20 m high module weighs less than 30 kg. Theoretically it is possible for two people to set the stand up," explains Oskar Zieta.

The stand area at this year's imm cologne is long and narrow, which means that the modules are arranged like a chain, one behind the other. The interior of the corridor which is formed is shaped by the central cross member. It is interrupted at regular intervals, wherever individual modules are rotated by 180° and the cross member is accordingly in the lower third section. This asymmetry optimises the stability of the entire structure.

In order to provide protection during the frequent transport of the modules, which fit into each other, corrosion-free unpainted Inox steel was used, which means that there is no scratching or peeling of paintwork. In addition the highly polished, reflecting surface highlights the crystalline structure of the design.

Thanks to our partner and sponsor Andreas Messerli Kommunikation im Raum (project management, exhibition building and logistics) for assembling the Architonic Concept Space III.