Future Fibres: Techtextil 2017

Historia de la marca de Ulrich Büttner

Neustadt an der Weinstrasse, Alemania

08.03.17

From 9 to 12 May 2017, TECHTEXTIL in Frankfurt am Main will provide an overview of the current state of textile architecture as well as future developments in the field.

With its metallic silver look, the added tribune ring lends Polman Stadium in Almelo, Netherlands, a futuristic appearance

With its metallic silver look, the added tribune ring lends Polman Stadium in Almelo, Netherlands, a futuristic appearance

×To most people, textile architecture is synonymous with spectacular spans of fabric and expressive design. Textile building envelopes are also becoming increasingly common, however. And not only are new and sophisticated characteristics continually being realised in fabrics, but these materials are now delivering the proof of their projected longevity. From 9 to 12 May 2017, Techtextil in Frankfurt am Main will reflect the state of developments in this field and point towards its future.

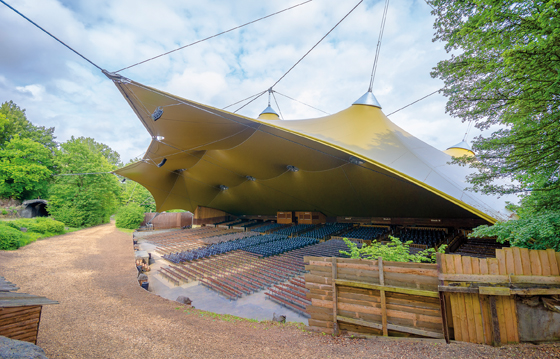

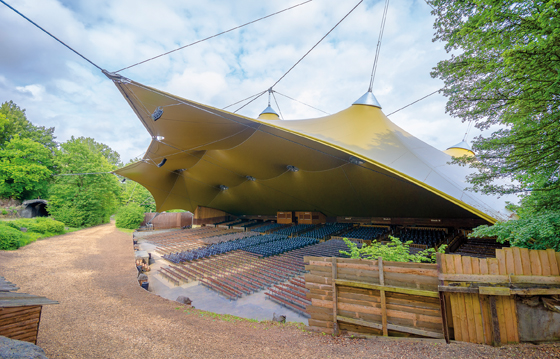

An early example of textile architecture is the membrane roof of the “Nature Stage” for the Karl May Festival in Elspe, Westphalia. When it was completed in 1978, it was the largest winter-proof roof construction of its kind in Europe, providing 4,400 spectators protection from the sun and rain. Although the roof showed no weaknesses even after 37 years of constant exposure to the elements and could have done a perfect job for many years to come, the building owner wanted to freshen up the colour, and so decided to replace the membrane. The manufacturer Mehler Texnologies/Low & Barner was called on to develop a custom-designed membrane that visually would be a close match to the original. Thanks to the further development of fibres and coatings over the intervening decades, realising the roof skin – which is approximately 77 by 32-to-40 metres in area and is tensioned and anchored by means of cables – didn’t pose the same challenge as it had the first time. The 2,600-square-metre membrane made of Valmex Mehatop F, Type V, is currently expected to have a service life of at least 50 years.

After 37 years in the elements, the 2,600-square-metre membrane roof of the “Nature Stage” in Elspe was replaced. The owner wanted to freshen up the colour; technically, the old roof was in excellent condition. Photos: Koch Membranen

After 37 years in the elements, the 2,600-square-metre membrane roof of the “Nature Stage” in Elspe was replaced. The owner wanted to freshen up the colour; technically, the old roof was in excellent condition. Photos: Koch Membranen

×The Koza Arena in Istanbul is a tennis stadium that seats some 7,000 and hosts international tournaments. Ofis 16 Architecture sought a design solution that would unify the building’s roof and façade. The visitor is immersed in a luminous world in which not only the court but also all of the service zones benefit from the glare-free daylight that the opaque skin allows through. In the evening hours, when the venue is illuminated from within, it offers a magical sight – also due largely to this nano-coated white membrane made of Valmex FR 1000 Mehatop N, Type III (Mehler Texnologies/Low & Barner). The coating reduces the soiling of the skin to a minimum. The membrane is further reinforced by 1,500 square metres of extremely tear-resistant TF 600 mesh fabric.

Like a protective cocoon, the light-coloured membrane envelops the façade and roof construction of the Koza Arena tennis stadium in Istanbul, creating an interior space that is open and bright, yet intimate

Like a protective cocoon, the light-coloured membrane envelops the façade and roof construction of the Koza Arena tennis stadium in Istanbul, creating an interior space that is open and bright, yet intimate

×An air dome in Vienna demonstrates that textile solutions can also be the ideal choice for buildings other than huge, emblematic construction projects. Here, too, an existing structure was to be replaced, and a new building that would achieve a substantial reduction in energy use was called for. The architectural challenge for this three-court hall lay in the requirement to preserve the use of the existing technical fittings and machines. The contractor thus had to ensure the production of a membrane that would conform perfectly to the given dimensions: 46.76 x 36.83 x 10 metres. The fabric type 2(1) – art. 669 from Sattler Global was employed in the triple-layered shell construction. For its halls, the contracting firm PM Engineering S.r.l. of Milan conceived an external shell to protect against the weather along with two “floating” internal membranes, with each layer spaced slightly from the next. Advanced inner air conveyance prevents air from being blown onto the players and supplies the expansive interior with a steady current of warm air from above.

While air domes for tennis courts aren’t unusual, this structure in Vienna achieves optimised energy efficiency by means of a three-layer membrane and also features integrated LED lighting

While air domes for tennis courts aren’t unusual, this structure in Vienna achieves optimised energy efficiency by means of a three-layer membrane and also features integrated LED lighting

×Membrane surfaces have also long been used in building remodelling or expansion projects such as in Polman Stadium, the home of the Dutch football club Herakles Almelo. The facility, designed by Hans van den Dobbelsteen and completed in 1999, was given a second terrace and a new roof construction before the start of the 2015/16 season according to plans by pr8 architecten. For the façade encircling the added tier, the architects chose a metallic silver look, deciding on a Verseidag PVC-coated polyester membrane with a low dead load. The individual sections were made and mounted on the curved profiles in just a few days by the Poly-Ned company. The stadium now makes a highly technical and visually light an overall impression, with the textile ring encompassing the stadium like a gleaming metallic tyre.

At Polman Stadium in Almelo, Netherlands, the PVC-coated polyester membrane was mounted in sections within a few days. The stretched skin of the new “upper storey” has the appearance of metal at just a fraction of the weight

At Polman Stadium in Almelo, Netherlands, the PVC-coated polyester membrane was mounted in sections within a few days. The stretched skin of the new “upper storey” has the appearance of metal at just a fraction of the weight

×The buildings presented here offer a vivid demonstration that, even beyond the gaze of a sports-oriented world public, textile architecture can be realised aesthetically, quickly and economically using high-tech membranes. Cutting-edge materials serve innovative concepts, not an elitist image.

© Architonic