The Making of Architonic Concept Space IV

Text by Susanne Fritz

Switzerland

10.04.12

The Milan fair provides the ideal setting for the premiere of Architonic Concept Space IV. And this will be a global first because never before has the FluidSolids® material, developed over many years and patented by the prestigious Swiss designer Beat Karrer, been processed at into a product.

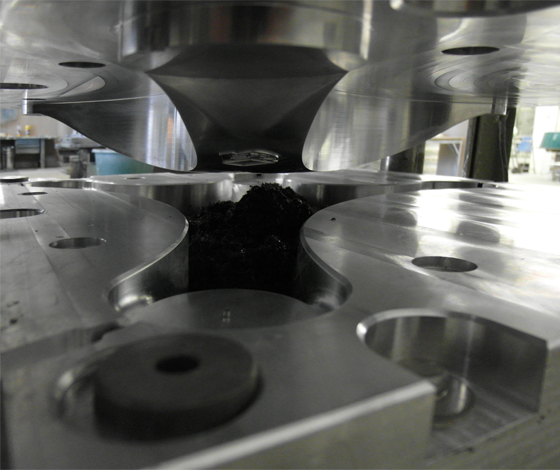

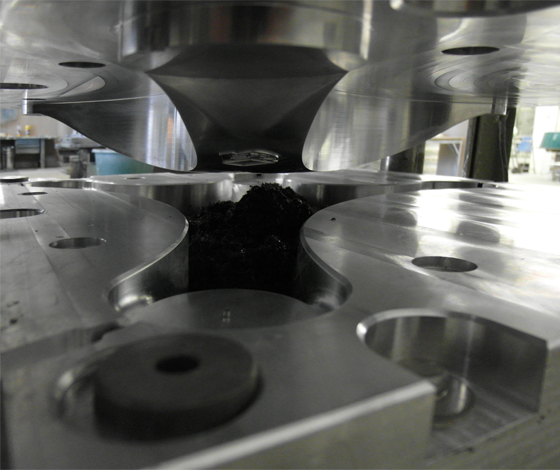

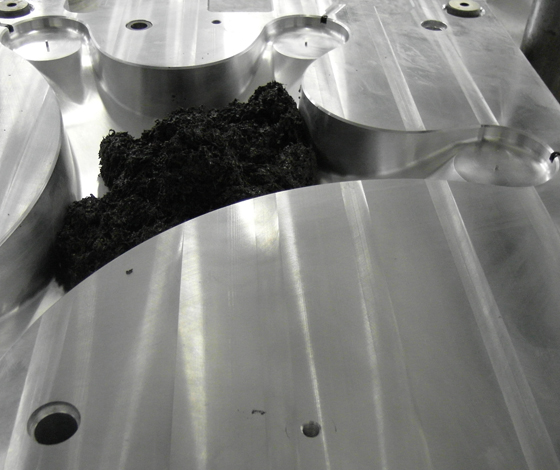

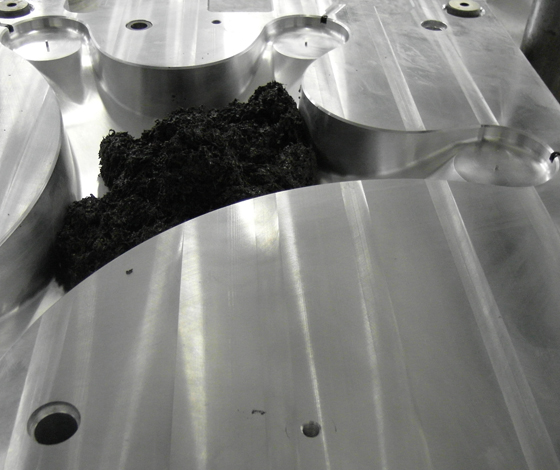

Mold of one element of Architonic Concept Space IV

The visionary concepts of the Architonic Concept Spaces are conceived with pioneering designers who collaborate with innovative production companies to merge the latest technologies and materials in a novel way.

As a result the new Concept Space IV follows on from the avant-garde concepts of its predecessors, which were created respectively by LAVA Architects, Gramazio & Kohler and Zieta Prozessdesign. Architonic Concept Space IV, too, once more sets new benchmarks, this time with a focus on sustainability, because the ground-breaking material created by Beat Karrer is made exclusively from renewable raw materials and is one hundred per cent biodegradable.

Beat Karrer in his studio with the prototype of Architonic Concept Space IV

In developing the material Beat Karrer had the aim of ensuring that his innovative material generates real value, making products and applications more flexible, stable, sustainable and cost efficient. The result of this process is FluidSolids®, a compound material which meets all these requirements and has already received recognition in the form of the Materialica Gold Award.

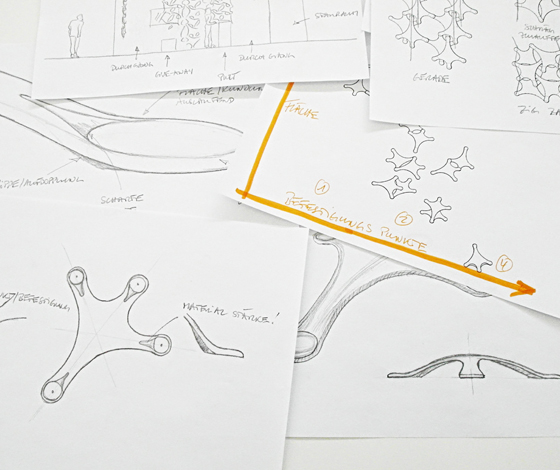

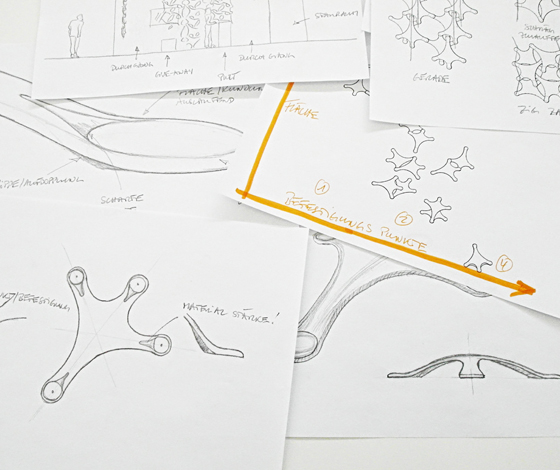

The elements of Concept Space IV are three-dimensionally deformed modules consisting of amorphous shapes, which can be endlessly combined with one another to create widely different structures. The repetition enables the interlinked elements to grow into the third dimension, concentrating themselves into densely interwoven forms. The result is large-meshed structures which play with densification and permeability, transparently combining spaces or separating them.

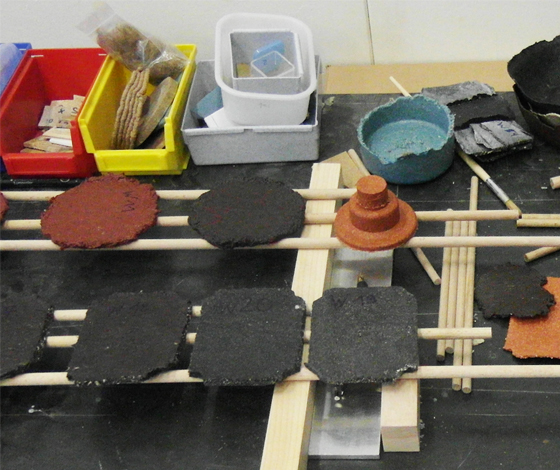

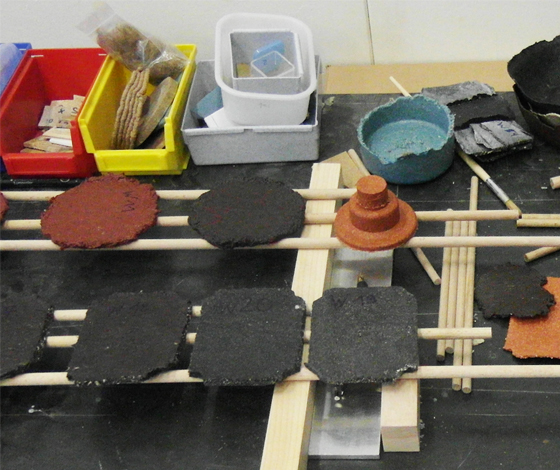

The elements of Concept Space IV are three-dimensionally deformed modules consisting of amorphous shapes

The elements of Concept Space IV are three-dimensionally deformed modules consisting of amorphous shapes

×From the wide range of possible production processes for the FluidSolids® material, such as moulding or extrusion, we decided in favour of the technique of pressing for the implementation of the new Concept Space. We found the ideal partner for the production of the individual elements in the Swiss firm of Faserplast. On the one hand Faserplast has, as a manufacturing company, outstanding expertise in the production of reinforced fibre components. On the other its own furniture collection NANOO by Faserplast provides the company with in-depth know-how with regard to the possibilities and requirements of new materials.

Mold of one element of Architonic Concept Space IV

However, the most fascinating aspect of FluidSolids® is that its physical properties can be 'programmed' in almost anyway required, both in terms of the desired look and with regard to the technical demands on the individual element. No agricultural area is required for the production of FluidSolids®, which is manufactured wholly from recycled industrial materials. It is biodegradable, non-toxic and odour free. The Architonic Concept Space is not just flexible and suitable for hybrid uses, but can also be fully decomposable, accordingly setting new benchmarks in terms of sustainability.

FluidSolids® is made exclusively from renewable raw materials and is one hundred per cent biodegradable

FluidSolids® is made exclusively from renewable raw materials and is one hundred per cent biodegradable

×