TECU® Zinn | Facade

Metal panels from KME

Product description

Concept

„Tinned copper for Roofing and Façade Cladding“

Colourful grey: elegance and durability

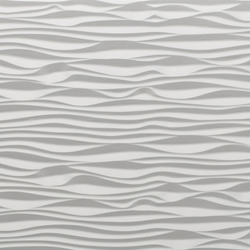

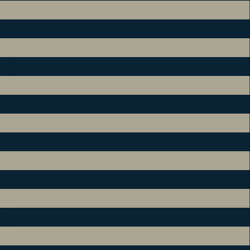

The elegant understatement of the exquisite matt grey surface harmonises excellently with many other building materials. And the connection between two exceptional metals combines the proverbial longevity of the carrier material with a metallic surface which, although not typical for copper, strikes just the right note.

To manufacture TECU ® Zinn, copper strips are specially tinned and surface-treated on both sides. The resulting surface gradually takes on the distinctive matt grey colouring when exposed to weathering.

4.1 Quality

„To do one thing without having to do without the other – where else is this so absolutely true?”

TECU® Zinn strips are manufactured in state-of-the-art production facilities according to DIN EN 1172 and KME’s own strict guidelines. They are made of Cu-DHP, oxygenfree, phosphorus-deoxidised copper with limited residual phosphorus. Cu-DHP is well suited for welding and soldering; its degree of purity is at least 99.9%, in accordance with DIN 1787 titled “Copper, Wrought Products”. Cu-DHP is outstandingly malleable, regardless of temperature and the direction of rolling.

TECU® Zinn surpasses the requirements of DIN EN 1172 with regard to tolerances and the most important technological values. This gives the processed surfaces their excellent visual appearance.

4.2 The surface

„It’s grey – but it’s still copper!”

TECU® Zinn is specially treated TECU® Classic copper that is tinned on both sides. The matt surface continues to develop over time when exposed to weathering. A warm, grey hue that harmonises well with other building materials gradually develops. The surface is pure tin, which, like copper, is extremely resistant to atmospheric effects and also complements the characteristics of copper. The material offers architects many interesting design options wherever there is a need for light, grey surfaces, while retaining all the technical advantages of copper such as its long life, resistance to reverse-side corrosion and its workability in all temperatures.

4.3 Processing and Installation

“Copper is reliable. That’s what makes it so versatile.”

The physical appearance of TECU® Zinn is influenced by the installation and the system applied. The combination of copper’s typical properties, such as malleability, high ultimate elongation, high melting point etc. lend TECU® Zinn its special suitability for all metal-specific processing techniques from traditional seaming to modern cladding. TECU® Zinn is processed like bright rolled copper with the usual tools and equipment using standard processing techniques such as folding, seaming and bending. As with copper generally, TECU® Zinn is excellently suited to soldering. However, due to the special features of the surface, a few important guidelines in regard to processing should be kept in mind.

Colourful grey: elegance and durability

The elegant understatement of the exquisite matt grey surface harmonises excellently with many other building materials. And the connection between two exceptional metals combines the proverbial longevity of the carrier material with a metallic surface which, although not typical for copper, strikes just the right note.

To manufacture TECU ® Zinn, copper strips are specially tinned and surface-treated on both sides. The resulting surface gradually takes on the distinctive matt grey colouring when exposed to weathering.

4.1 Quality

„To do one thing without having to do without the other – where else is this so absolutely true?”

TECU® Zinn strips are manufactured in state-of-the-art production facilities according to DIN EN 1172 and KME’s own strict guidelines. They are made of Cu-DHP, oxygenfree, phosphorus-deoxidised copper with limited residual phosphorus. Cu-DHP is well suited for welding and soldering; its degree of purity is at least 99.9%, in accordance with DIN 1787 titled “Copper, Wrought Products”. Cu-DHP is outstandingly malleable, regardless of temperature and the direction of rolling.

TECU® Zinn surpasses the requirements of DIN EN 1172 with regard to tolerances and the most important technological values. This gives the processed surfaces their excellent visual appearance.

4.2 The surface

„It’s grey – but it’s still copper!”

TECU® Zinn is specially treated TECU® Classic copper that is tinned on both sides. The matt surface continues to develop over time when exposed to weathering. A warm, grey hue that harmonises well with other building materials gradually develops. The surface is pure tin, which, like copper, is extremely resistant to atmospheric effects and also complements the characteristics of copper. The material offers architects many interesting design options wherever there is a need for light, grey surfaces, while retaining all the technical advantages of copper such as its long life, resistance to reverse-side corrosion and its workability in all temperatures.

4.3 Processing and Installation

“Copper is reliable. That’s what makes it so versatile.”

The physical appearance of TECU® Zinn is influenced by the installation and the system applied. The combination of copper’s typical properties, such as malleability, high ultimate elongation, high melting point etc. lend TECU® Zinn its special suitability for all metal-specific processing techniques from traditional seaming to modern cladding. TECU® Zinn is processed like bright rolled copper with the usual tools and equipment using standard processing techniques such as folding, seaming and bending. As with copper generally, TECU® Zinn is excellently suited to soldering. However, due to the special features of the surface, a few important guidelines in regard to processing should be kept in mind.

More about this product

Part of the collection

TECU® FACADES.

Manufacturer

KME

Family

TECU® Zinn | Facades

Architonic ID

1170808

Similar products

Related Projects

This product has been archived. Product information may no longer be up to date.

![EQUITONE [tectiva] - Facade Design | Concrete panels | EQUITONE](https://image.architonic.com/img_pro1-6/129/9192/equitone-tectiva-facade-panel-passive-house-01-sq.jpg)