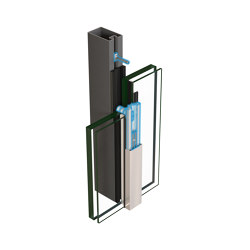

Hirt Descender Front

Patio doors from Hirt Metallbau

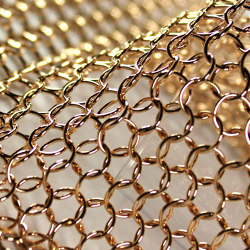

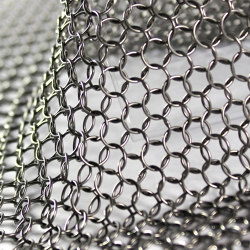

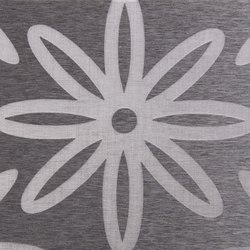

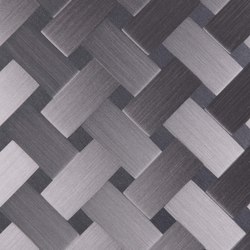

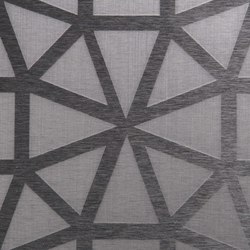

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

- Family gallery

Product description

Concept

Applications

The proven descender front developed by Hirt Metallbau AG is employed as a thermally insulated element in the external envelope of a building. This system offers several key advantages: large-area, room-height opening, floor transition with no threshold, and leaves that are parked in a basement mechanical room without taking up valuable space.

The system leaves scope for custom adaptations, and the customer’s wishes are incorporated into the design. Extra-narrow frame and sash exposures are available if applicable.

The system is available as a single unit for mounting in a masonry opening, for example, or multiple units can be installed side by side.

In addition to full-area fixed glazing, many variations and combinations are available: entry doors, vertical sash windows, muntin leaves, all-glass façades, wood accents and masonry, to name just a few.

Operating mechanism and safety

The descender front is operated by an electromechanical drive.

We supply and install the motor, controls and other needed components.

The base version is intended for operation from a position with a view of the descender front. A “deadman” feature is incorporated so that the open/close switch must be pressed and held while the operator observes the movement of the front. Automatic control is available as an option.

The Hirt descender front conforms to the applicable EKAS safety standards.

Functional principle

The neutrally counterweighted leaf is suspended on chains that pass over rollers attached to the bottom face of the floor slab. If the basement does not offer enough headroom, the counterweight system can be deflected and the weight doubled so that only half the travel is needed.

The front is guided by tracks at the sides. The precision mechanism guarantees absolutely noise-free operation.

Sealing principle

Sealing works on the labyrinth principle together with direct pressure.

Two seals running around the inside face and two more around the outside face ensure comfort and provide the most up-to-date thermal and acoustic insulation.

A warm-air duct can be installed near the floor to compensate for the lack of heat reflection by the glass.

Maximum sizes

The standard version is good for descender fronts up to a maximum size of 6 m wide and 4 m high and a maximum weight of approx. 1500 kg. Static modifications to the sashes, tracks, suspensions and other components are necessary for larger sizes.

Please inquire about special formats or weights.

Installation arrangements

The descender front can be installed in all ordinary façades: double-shell masonry walls, solid walls with external insulation, externally cladded walls with rear ventilation and modern glass-and-metal façades.

Casings are to be used as appropriate.

The clear height, outside dimensions of the unit, headroom of the mechanical room and other measurements can be read off the system plans. The floor opening should have a minimum width of 380 mm, or 470 mm for the postless version.

Please be sure to discuss the installation arrangements with us during the design phase.

Mechanical room

The mechanical room provides parking space for the open descender front and accommodates the counterweight system. The motor, drive shaft and other electrical components are also installed here.

The headroom must be sized in accordance with the opening travel of the descender front or the counterweight travel.

The mechanical room should be sized to allow for cleaning, repair and service operations.

A water drain or pump must be present at the lowest point of the mechanical room.

In the interest of personnel safety, the mechanical room must be laid out so that the counterweights are not freely accessible. The doors to the mechanical room must have a limit switch to halt operation of the system whenever anyone enters the room.

Electrical power and control (automated models only)

The building operator is responsible for installation of cabling for the motor, limit switches, control boxes and line power receptacles by an electrician.

We supply conduit routing data, conductor sizes, motor power ratings and wiring diagram.

Our microprocessor control system combines modern technology with adaptability. Options from our catalog, such as remote control, safety edge switches, electric eyes, automatic sensors, etc., can be integrated without difficulty.

Maintenance

The system is designed to state-of-the-art standards, with high-quality components that minimize malfunctions and require the least possible maintenance.

Periodic inspections of the mechanisms and safety elements as provided in the guidelines can be covered by a service agreement to guarantee trouble-free operation and value retention.

The proven descender front developed by Hirt Metallbau AG is employed as a thermally insulated element in the external envelope of a building. This system offers several key advantages: large-area, room-height opening, floor transition with no threshold, and leaves that are parked in a basement mechanical room without taking up valuable space.

The system leaves scope for custom adaptations, and the customer’s wishes are incorporated into the design. Extra-narrow frame and sash exposures are available if applicable.

The system is available as a single unit for mounting in a masonry opening, for example, or multiple units can be installed side by side.

In addition to full-area fixed glazing, many variations and combinations are available: entry doors, vertical sash windows, muntin leaves, all-glass façades, wood accents and masonry, to name just a few.

Operating mechanism and safety

The descender front is operated by an electromechanical drive.

We supply and install the motor, controls and other needed components.

The base version is intended for operation from a position with a view of the descender front. A “deadman” feature is incorporated so that the open/close switch must be pressed and held while the operator observes the movement of the front. Automatic control is available as an option.

The Hirt descender front conforms to the applicable EKAS safety standards.

Functional principle

The neutrally counterweighted leaf is suspended on chains that pass over rollers attached to the bottom face of the floor slab. If the basement does not offer enough headroom, the counterweight system can be deflected and the weight doubled so that only half the travel is needed.

The front is guided by tracks at the sides. The precision mechanism guarantees absolutely noise-free operation.

Sealing principle

Sealing works on the labyrinth principle together with direct pressure.

Two seals running around the inside face and two more around the outside face ensure comfort and provide the most up-to-date thermal and acoustic insulation.

A warm-air duct can be installed near the floor to compensate for the lack of heat reflection by the glass.

Maximum sizes

The standard version is good for descender fronts up to a maximum size of 6 m wide and 4 m high and a maximum weight of approx. 1500 kg. Static modifications to the sashes, tracks, suspensions and other components are necessary for larger sizes.

Please inquire about special formats or weights.

Installation arrangements

The descender front can be installed in all ordinary façades: double-shell masonry walls, solid walls with external insulation, externally cladded walls with rear ventilation and modern glass-and-metal façades.

Casings are to be used as appropriate.

The clear height, outside dimensions of the unit, headroom of the mechanical room and other measurements can be read off the system plans. The floor opening should have a minimum width of 380 mm, or 470 mm for the postless version.

Please be sure to discuss the installation arrangements with us during the design phase.

Mechanical room

The mechanical room provides parking space for the open descender front and accommodates the counterweight system. The motor, drive shaft and other electrical components are also installed here.

The headroom must be sized in accordance with the opening travel of the descender front or the counterweight travel.

The mechanical room should be sized to allow for cleaning, repair and service operations.

A water drain or pump must be present at the lowest point of the mechanical room.

In the interest of personnel safety, the mechanical room must be laid out so that the counterweights are not freely accessible. The doors to the mechanical room must have a limit switch to halt operation of the system whenever anyone enters the room.

Electrical power and control (automated models only)

The building operator is responsible for installation of cabling for the motor, limit switches, control boxes and line power receptacles by an electrician.

We supply conduit routing data, conductor sizes, motor power ratings and wiring diagram.

Our microprocessor control system combines modern technology with adaptability. Options from our catalog, such as remote control, safety edge switches, electric eyes, automatic sensors, etc., can be integrated without difficulty.

Maintenance

The system is designed to state-of-the-art standards, with high-quality components that minimize malfunctions and require the least possible maintenance.

Periodic inspections of the mechanisms and safety elements as provided in the guidelines can be covered by a service agreement to guarantee trouble-free operation and value retention.

More about this product

Categorised in Windows - Doors - Window types - Patio doors - Down sliding windows - Descender doors - Building construction.

Manufacturer

Hirt Metallbau

Family

Hirt Descender Front

Architonic ID

1087333

Similar products

This product has been archived. Product information may no longer be up to date.