Trend Report (I): Milan 2015

Scritto da Le Vin Chin

Basel, Svizzera

05.05.15

Halfway through my visit to the Milan design week, this year, I posted a cri de coeur on Facebook: “Major FOMO. No time! No time!” The brevity only emphasised the point.

Facebook had already blown up in preparation for the fair the previous week, Instagram was relating all the incredible stuff other people were seeing right then, in real time. Milan’s design week, in the digital age, gives you an incredible overview: you get to see the coolest installations and the most interesting pieces online before you’ve even set foot out of your AirBNB door. And doesn’t that show up the social trend and the design trend of the moment, our constant, continuous need for content, information and entertainment as enabled and encouraged by our new technological capabilities?

Here is the first of three main trends seen at Milan’s design week 2015:

Open-Source Design and Digital Making

Re-use has long been a staple of the young designer repertoire. It demonstrates right-on commitment to sustainable and ecological living, and it offers scope for young designers to show their creativity. But where do we see the principles applied in commercial design? It’s a rare case (think Freitag, for one example) when re-use gets into the mass market and commercial mainstream. One avenue is for designers to ensure their products have longer times to obsolescence; another, to ensure the final product can be easily recycled, or even break down into raw components. A newer approach takes its lead from the world of open-sourcing, in which component parts of a design are expressly designed to have multiple uses in multiple objects. When one object breaks down, or is no longer needed, the component parts may live on in other configurations, in other products.

This whole concept was visualised very neatly by the team behind the Hacking Households exhibit at the Palazzo Clerici, which examined modern design and production processes against a backdrop of digital manufacture and maker culture. (Look out for the great video on their site.) The end result is “an eco-system of open objects … where objects are designed, developed, and produced democratically within open communities.”

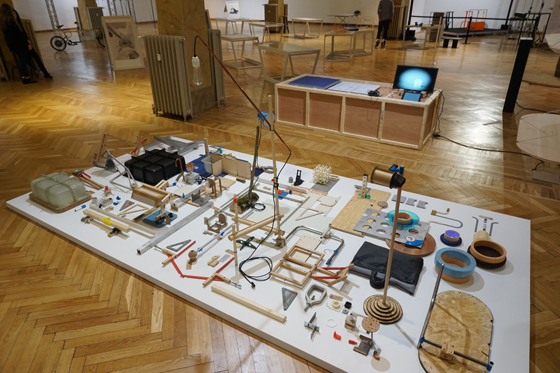

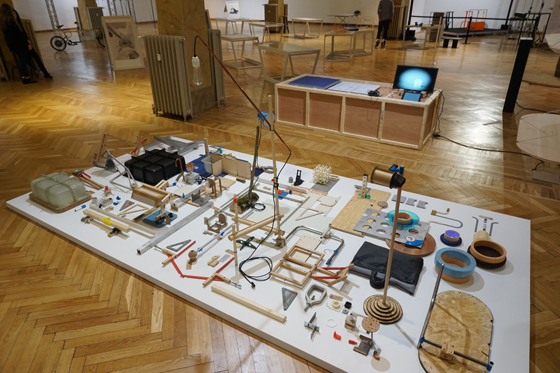

A key example was the results of Thomas Lommée’s OpenStructures (OS) Relatives Masterclass with USM and the Domaîne de Boisbuchet, at the Salone dei Tessuti. Each participant of the workshop, based on Lommée’s OpenStructures concept, was challenged to “design and build an object of which at least one part is used in the design of a fellow student.” In this way, the lifecycles of the objects can theoretically expand onward forever.

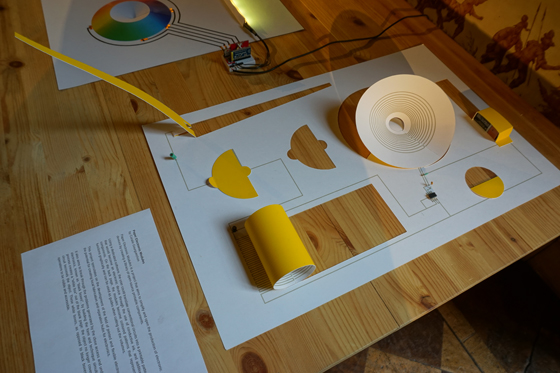

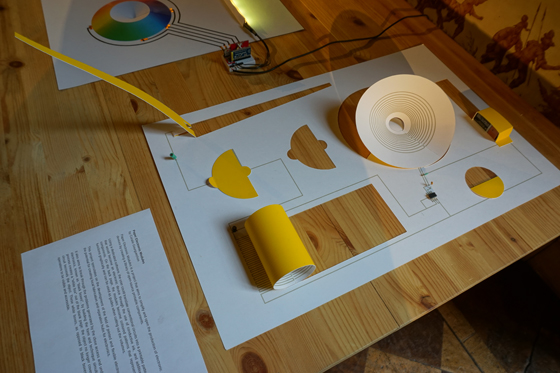

The Open Making Platform by OpenDesk; photo: Le Vin Chin

As in years past, the Palazzo Clerici led the vanguard in the examination of technology trends and the impact on design and manufacture. In only its second year curating and organising the events and interventions at the location, the Atelier Clerici also had exhibits based on digital manufacture and home maker culture. The Open Making Platform by OpenDesk showed examples from their platform, which brings together designers, makers (digital fabricators, i.e. 3D printers, CNC machiners, laser cutters, etc.) and potential customers. All parties theoretically gain from the idea: designers get their distribution channel (they get to decide what licensing model they want to impose), makers get work, customers get their product.

In the same vein, Make it chp...? showed single-use 3D printable orchid-jewellery designs that can be made by makers licensed with Make it LEO technology. LEO stands for “Limited Edition Object” and the technology allows the designer to define how often and where a design can be made, enabling the idea of a limited edition object to coincide with the efficiency of local manufacture. The orchid designs for this project were created by the Studio Minale-Maeda who also presented their other 3D printed solution: “Keystones,” a universal connector that can be used to make anything.

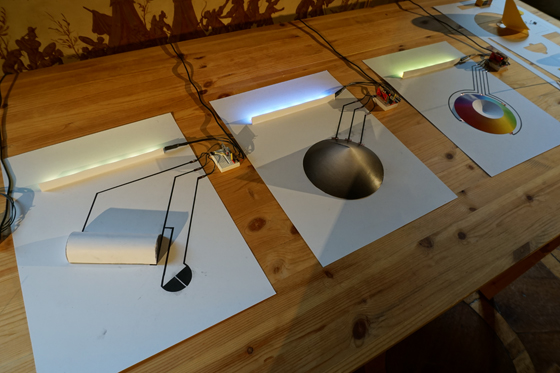

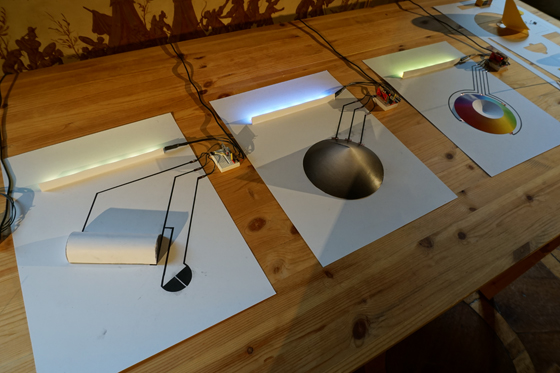

But innovation in home maker printing doesn’t just have to be 3D. PUI + PEM envisions a system of interfaces for paper-based electronic products based on circuits printed with conductive ink, Paper User Interfaces (PUI), and a library of open-source printable components, Paper Electronic Modules (PEM).

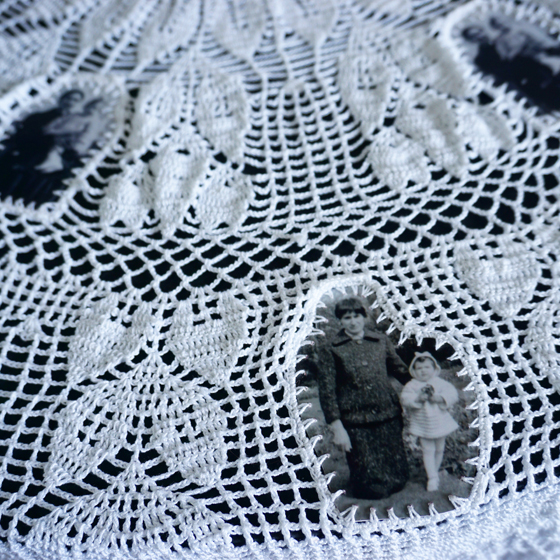

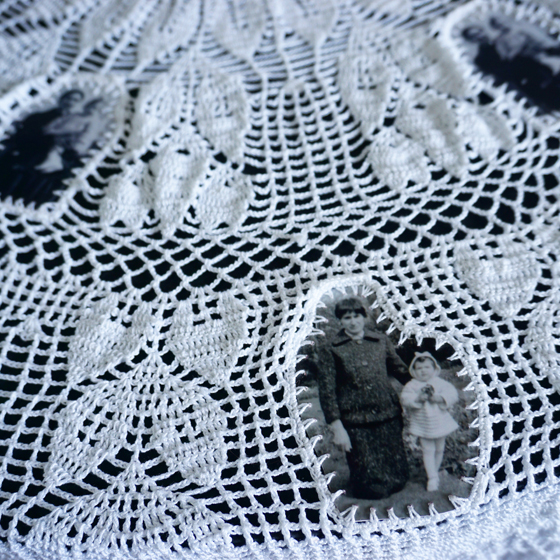

Of course, more traditional re-use and appropriation was fully evident at the various design week shows. From top to bottom: “Hanger Chandelier” by Mariko Tsujimoto, at Salone Satellite; bench made of chairs and door, by Mario Ghiretti and Frederica Guareschi, at Lambrate; "Mirror" armchair by Sarah Schäpsmeier from the On The Edge Project of the Detmold School of Architecture and Design, at Lambrate; "Family Bonds" by Esperanza Perkins of the University of the Arts London, at Lambrate.