NOGI + THE FIRST CARBON TABLE TOP IN COMPOSITENCE TECHNOLOGY

Zieta Prozessdesign teamed up with Compositence and brings together two innovative technologies FiDU and Composite Process to create the table: NOGI + CARBON TABLE TOP.

Compositence manufactured designed by Oskar Zieta dedicated and unique carbon table top for NOGI table construction. We and Compositence decided to co-operate in order to create not only one-of-a-kind products but especially ultra-light and durable constructions.

We are employing computer controlled processes that involve high precision tools to create three dimensional constructions’ elements which are used to build the ultralight table construction. Compositence technology creates extraordinary and unique carbon surface structures that can’t be achieved by other technologies.

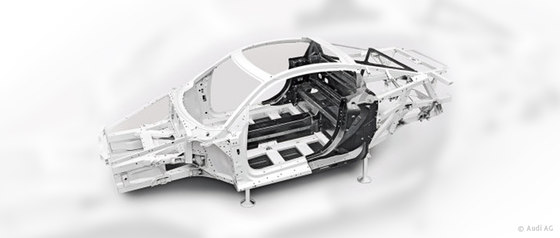

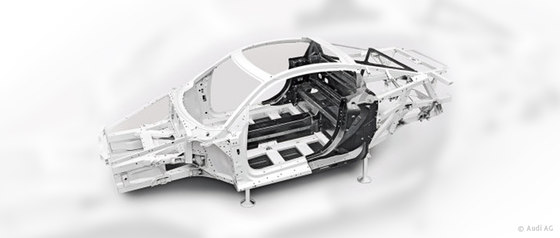

This technology is use for high-tech professional sports car. In this way the table top created by Compositence is perfectly suitable for the NOGI table construction with its bionic and one-of-a-kind form obtained during free internal pressure forming.

The synergy between design and technology allowed us to produce one of the lightest and durable and most unique but still mass-produced tables on the market.

This is the first product of next steel-carbon and aluminium-carbon hybrids which Zieta Prozessdesign will show in near time.

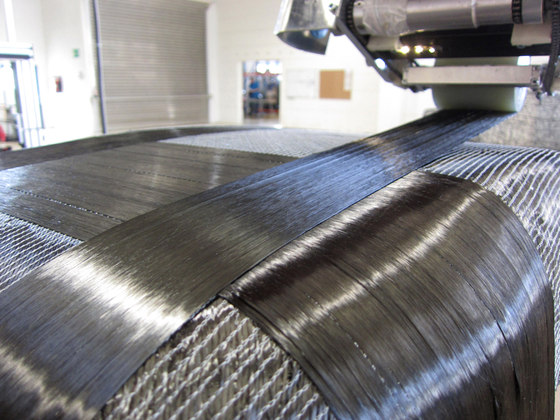

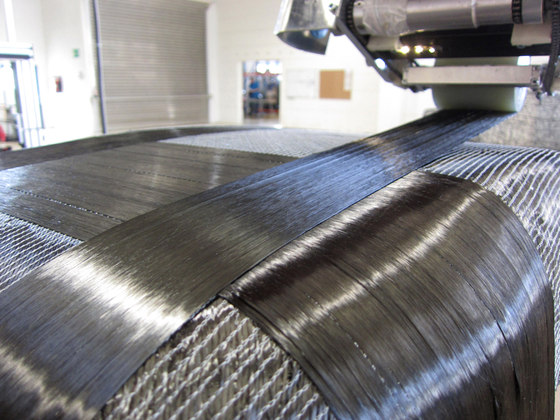

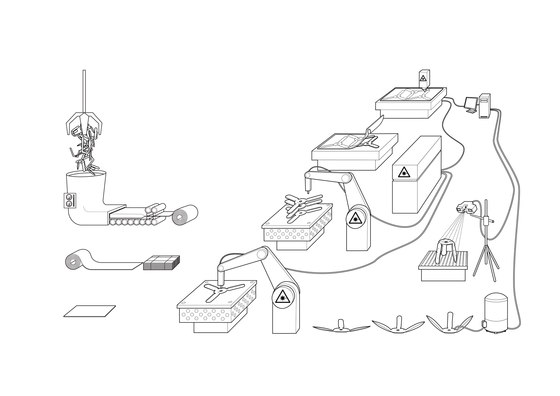

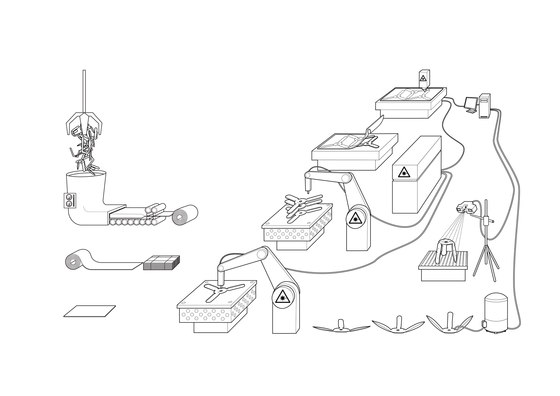

COMPOSITENCE PROCESS

The process uses pure carbon fiber from the spool, the most affordable raw material, to make a homogeneous carbon fiber band consisting of multiple carbon fibers. Since carbon fiber is a luxury raw material, it is important to use it very sparingly. Wasting of carbon fibers need to be reduced to a minimum, in the product design and the production process, especially cut-off.

The Compositence process uses this expensive raw material very sparingly, as it only places the carbon fiber where it is actually needed in the component. And the fibers are placed exactly in the orientation they are needed, based on the stress loads for the component. This allows for better component quality with far less carbon fiber costs.

In brief, the Compositence process uses less fiber, but it uses it more efficiently and in fully automated, direct 3D production.

FiDU PROCESS

FiDU is the most innovative technology developed by Zieta Prozessdesign. FiDU is an abbreviation of the German term “Freie-Innen-Druck-Umformung” – Free Inner Pressure Forming. It means that two shapes cut from steel sheets are welded around their edges and inflated into a 3d object. The deformation of flimsy metal sheets caused by the pressure makes them stable and rigid. Moreover – it makes it so durable, that it can be categorized as an ultra-light construction. It takes only two thin steel sheets to create a complicated and very durable object made of steel in FiDU. It allows us to create innovative, customised, bionic shapes and to produce them in small series using very efficient production processes. The technology can be applied to produce ultra-light constructions of great weight capacity – for product design and architectural elements.

Zieta Prozessdesign

Designer: Oskar Zieta