Metal modified through precision-controlled design

Texto por TLmag

Brussels, Bélgica

21.01.15

Oskar Zieta is arguably one of Poland’s most renowned designers. He is also Head of Industrial Design at the New School of Form in Poznań (2010) created by Li Edelkoort, where he is now, continuing his ambitious path to innovate, create, produce, sell and pass on his knowledge. The chief architect of his own successful inventions (inflatable metal), he doesn’t hesitate for a second when asked to demonstrate how metal transforms into a three-dimensional state. He is also the guest of honour at Rendez-vous de la Matière in Paris, as part of the 5th anniversary celebrations of TLmag, in collaboration with Bookstorming and Poujoulat

Oskar Zieta with his 3+ collection handling a Plopp stool

Combining research, development and innovation, Oskar’s strength is his family business based in Wroclaw, which allows him to create and produce. At Zieta Prozessdesign, which he runs with his sister Maja, he surrounds himself with a multidisciplinary team composed of architects, designers, engineers and cutting-edge technologists. Oskar takes up the challenge of creating new products while seeking optimal solutions for clients, whether it be a piece of art, design or contract work.

Lightness, durability, efficiency, surprising effects…Oskar has got his sights set firmly on the future and uses advanced technologies to customise his own products and those of his customers. The custom made, industrial approach, which applies to form, function, a unique piece or limited edition run, is the key to his success. The outcome is under control but there is still a margin of randomness that can slightly change the appearance, despite the intervention of a preprogrammed machine.

Plopp collection, the FiDU technology offers a range of options to inflate metal

High performing, ultra light inflated metal

Recognised and distributed all over the world, Plopp, launched in 2009, a product created using the FiDU technology he developed during his research at ETH University in Zurich in 2007, is probably Zieta’s most iconic collection. The challenge had been for him to take advantage of steel, or stainless steel, as a construction element and optimise its stability, its price, its form and function.

This led to the discovery of two outstanding technical solutions: FiDU Bridge (6 m, 174 kg) and FiDU Ball (4,8 metres high). He describes FiDU as “a technology that enables you to produce playful objects. It can be just as effective when applied to a series of mass-produced inflatable metal items or unique, artistic pieces like the Crater sculptures by Arik Levy.

Crater sculptures by Arik Levy, Passage de Retz, Paris, solo exhibition 2012

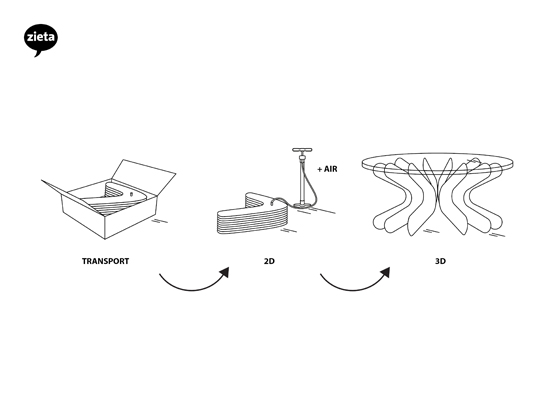

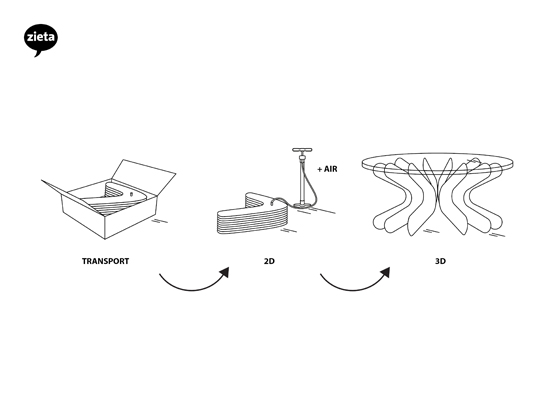

From the perspective of the industrial process, FiDU (from the German “Freie-Innen-Druck-Umformung”, or Free Inner Pressure Forming) allows you to customise the production starting from two shapes cut from sheets of metal (either steel or stainless steel) which are subsequently bent at an angle then deformed under internal pressure (water, oil, air) controlled by a machine.

Transforming (inflating) a two-dimensional shape so that it becomes a three-dimensional object, is a way of stabilising the material which becomes rigid and durable. The result is an astonishing, ultra lightweight product that aesthetically integrates into our contemporary lifestyles.

Like us, the object travels from place to place, interacts and is at the forefront of technology.” Oskar has set his sights high: FiDU can also help to create industrial products, but also architectural elements for facades and public spaces, and even aerodynamic applications for the aerospace industry. Zieta, with its process to easily create forms using FiDU, clears the path for the full recyclability of the raw material and a possible future for ‘upcycling’, which will lead to energy savings through ‘flat pack’ packaging solutions, and will contribute to a lowering of CO2 emissions due to the optimisation and reduction in weight of the material.

The 3+ collection inspired by Meccano

For his new collection, 3+, that was launched at Most Salone in Milan last year, Oskar has developed a perforated steel sheet sandwich that, from a series of standard modules comparable to a real game of Meccano, allows him to explore the world of modern construction systems. Working closely with his design studio, engineers and production team, he has come up with a collection that is as versatile as FiDU technology. It certainly provides more flexible and modular results when it comes to designing private and professional spaces. One can imagine 3+ as a new, easy-to-assemble office desk or shelving system that you can customise to your heart’s content.

3+ collection, a system inspired by Meccano with multiple interior design combinations, 2014

Zieta, a design brand with a global reach

Even if the northern Europeans were the first to embrace his products back in 2008 - companies like Magazin, HAY, Manufactum or Stilwerk - Zieta quickly realised that if he wanted his business to compete on a global market, his distribution would have to be on a global scale. He also opted to remain open to collaborations; not just for producing own collections, but also those of designers and artists where he was able to stretch himself and rise to different types of technical (and aesthetic) challenges. Co-creation is probably one of the keys to his success. He manages to convince designers like Ross Lovegrove or Arik Levy to produce remarkable pieces of work using his inflatable metal technique in Poland. It’s no secret that to achieve that level of excellence you need a fully-fledged production site.

The travelling Architonic booth, designed by Zieta, 2013

There is also the market for art and design as well as art installations - sources of even more freedom and experimentation for Zieta, who is busy creating exceptional pieces for Toolsgalerie in Paris: the Plopp stool and Chippensteel chair in copper, aluminium and other materials. Oskar’s multi-faceted profile contains all the elements to surprise us now and for many years to come.

---